Yes to a point, your not actually removing anything, but changing the properties by heating and cooling the material.

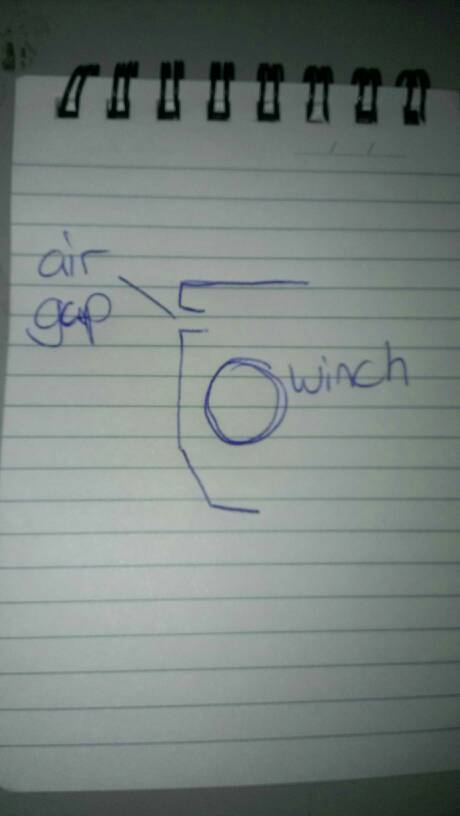

Yes, you could use 5 for the centre part where the winch sits, but if given some shape like the bigger named bars 4 will be plenty again.Would 4mm plate be thick enough for the front bar??

Again big named bars are 3mm.

Which joint are you saying to use ??

Attachment 26821

Finishing off the project is easy i have flap discs, grinding and cutting discs and a few different die grinding dremals (stone and steel) its just the fine technical details are what puzzle me ATM.[/QUOTE]

No.1 mate. Lots of tacks on the inside, full weld the outside, but stagger the welds...

Kallen Westbrook

Owner of

Westy's Accessories

Reply With Quote

Reply With Quote