-

21st January 2018, 06:38 PM

#981

.........

For sure thanks mate, the 6.5NA’s Alts rotate clockwise from front view same as the boys GQ’s. Just checked the internal tiny fans and yes they appear to be set for expelling air forward.

Sent from my iPhone using Tapatalk

-

-

21st January 2018 06:38 PM

# ADS

Circuit advertisement

-

21st January 2018, 06:42 PM

#982

I am he, fear me

Originally Posted by

MB

For sure thanks mate, the 6.5NA’s Alts rotate clockwise from front view same as the boys GQ’s. Just checked the internal tiny fans and yes they appear to be set for expelling air forward.

Sent from my iPhone using Tapatalk

Right... IMHO the next thing to check is the driven pulley dia (as suggested by poindexter)

The 6.5s are slower revving again than the TD42's.

FWIW I'll go check mine

Dolphins are so smart that within a few weeks of captivity, they can train people to stand on the very edge of the pool and throw them fish.

-

The Following User Says Thank You to the evil twin For This Useful Post:

-

21st January 2018, 06:46 PM

#983

.........

Cheers ET, I did make sure of that too before I purchased and the new pulleys OD was say only a few mm’s smaller than the BD I guess original Mitsubishi one on there when bought complete already.

Sent from my iPhone using Tapatalk

-

-

21st January 2018, 06:48 PM

#984

Mark, from what I have read the alternator will run hot at anytime. The issue is how the heat affects the rectifier /diodes in the rectifier. I am thinking our under bonnet temps exceed the operating temps of the alternator electronics and hence they crap out - heat equals resistance. Not having a big arse fan to cool the alternator will not be helping. I run a 3" marine blower to cool my alternators when it gets hot. At the end of the day you want your electronic controls as cool as possible - remember the diode expansion module i told you about?

If you send the current across 18 diodes instead of 6 they are individually doing less 'unit work' hence they heat up less from the electrical load. this does not have anything to do with the actual under bonnet load from the temps, but it gives your alternator more capability to generate at max current if the individual units are cooler - does this make sense?

-

The Following User Says Thank You to PeeBee For This Useful Post:

-

21st January 2018, 06:49 PM

#985

.........

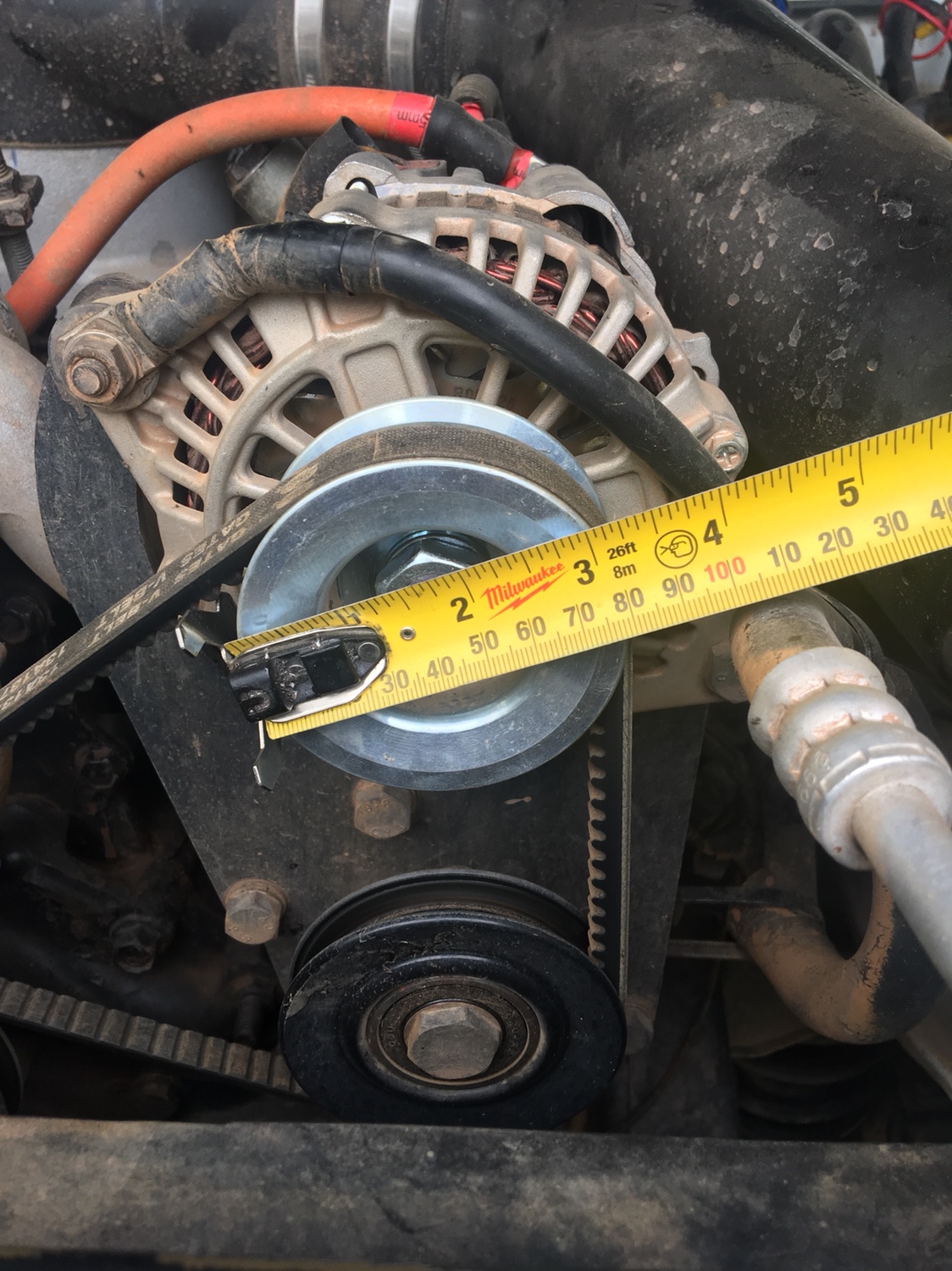

A poofteenth under 80mm OD checked here thanks mate.  V belts obviously slightly smaller ID measurement.

V belts obviously slightly smaller ID measurement.

Sent from my iPhone using Tapatalk

-

-

21st January 2018, 07:04 PM

#986

.........

Originally Posted by

the evil twin

The 6.5s are slower revving again than the TD42's.

FWIW I'll go check mine

Hmmmm, I don’t believe I checked that part thanks mate! From memory TD42s are around 750rpm idle and my Chev’s happy at 500-550rpm twactor styling. I never push it too much past say 3,000rpm flogging it :-)

Sent from my iPhone using Tapatalk

-

-

21st January 2018, 07:09 PM

#987

I am he, fear me

Mine is 60mm at the flange, approx 55mm at the drive face as the flanges are approx 2mm high.

Sooo... FWIW... my ALT will be spinning much faster the yours.

Is your pulley the same dia pulley it was supplied with for a TD42 or did you reduce it for the 6.5?

The other variable would be the dia of the crank pulley which is what determines belt speed but IMHO as there are other accessories all driven by the belt like A/C, P/S etc you would think the belt speed should be similar between 3 belt and serpy

Dolphins are so smart that within a few weeks of captivity, they can train people to stand on the very edge of the pool and throw them fish.

-

The Following User Says Thank You to the evil twin For This Useful Post:

-

21st January 2018, 07:13 PM

#988

.........

All Things Chev

Originally Posted by

PeeBee

.......does this make sense?

Thank you Phil mate, it kind of does although you know too well I am an electrical nuffy! Keen here to just make 100% sure first that the mechanics of it all are all correct brother:-)

Sent from my iPhone using Tapatalk

Last edited by MB; 21st January 2018 at 07:16 PM.

-

-

21st January 2018, 07:34 PM

#989

.........

Originally Posted by

the evil twin

Mine is 60mm at the flange, approx 55mm at the drive face as the flanges are approx 2mm high.

Sooo... FWIW... my ALT will be spinning much faster the yours.

Is your pulley the same dia pulley it was supplied with for a TD42 or did you reduce it for the 6.5?

The other variable would be the dia of the crank pulley which is what determines belt speed but IMHO as there are other accessories all driven by the belt like A/C, P/S etc you would think the belt speed should be similar between 3 belt and serpy

Cheers mate, huge Alt pulley size difference there :-(

Yep, it is the same pulley supplied and near identical size to the failed Mitsubishi that was already on there. Going to go check the crank pulley size now :-) @PeeBee mate, your NA Mitsubishi Alt from factory failed pretty quick too maybe?

Sent from my iPhone using Tapatalk

-

-

21st January 2018, 07:44 PM

#990

.........

All Things Chev

Ok, crank pulley OD on the 6.5NA V belt jobbie here is 195mm ish. So.... 195mm to 80mm at 1:1 drive = ? @ PeeBee please mate :-) !

Sent from my iPhone using Tapatalk

-

V belts obviously slightly smaller ID measurement.