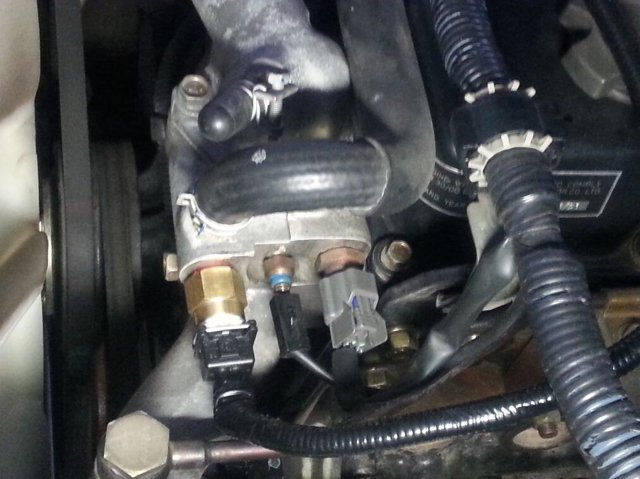

Fitted VDO electronic temp gauge.

& a new 115amp alternator, ebay job.

ordered a 150amp intervolt dual battery controller.

Installed a new anderson with 8G cable to the soon to be installed deep cycle,

also ran a lead running back from the anderson into the rear to replace the old power supply for the fridge.

I came across a 120amp controller that looks very similar to Intervolts smaller 100 amp model.

Good stuff, that will suit the new alternator!

so similar thought it had to be made by them, looked identical going by the front controls & art work etc.

nearly purchased it except it never mentioned if it was dual sensing, made inquires, was informed it was a copy cat unit.

I'd mention the retailer but don't want to walk on wobbly ground, lets just say we jnow them, you work it out.

Dual sensing can detect if your charging the aux battery with an external charger, so if the main is also in need of a charge, it can send some charge there also.

All the in/out parameters of the intervolt are user adjustable which makes it very flexible.

Funny part the 100,120 & 150 amp controllers if ya look for 5 min on the net could be purchased for $199 each.

yeah sure its a pricey way of doing it, but automotive contact type relays switching higher power can & do fail with some very expensive consequences,engine bay fires are one, seen it happen.

First search I did on the well known red$$K controller came back, How I fixed my red$$k, pulling it apart to clean the contacts as they were burnt and were pulsing the voltage, No thanks, This one is solid state, No moving parts.

Reply With Quote

Reply With Quote