Link below for further info of my post MR.

http://www.full-race.com/articles/efrturbotechbrief.pdf

Oil feed line starting from the block is an M10 x 1.5 90 elbow to -4an. The length of the braided line is 300mm.

Note: Line length is centre to centre of the ports so tell Pirtek/Enzed or whoever you are using down there so they can compensate for the elbow lengths and fittings themselves.

You will need a 90 bend into the top of the turbo for the oil feed as well -4an.

Oil drain.

Get that oil drain fitting explained earlier with the ID 15mm. Get rubber hose to suit into your exiting oil drain fitting on block. We will cut that to suit on the day. make sure you have clamps to suit.

MTQ sell Sonic Branded gear and you can get a 3/4 id hose that has a 90 molded into it. Make sure your drain fitting is 3/4 od.

Water feed starting from block.

I fed mine from the coolant drain on the block for some reason, creature of habit I guess. Your block will also have the port on the left hand side of oil relief which should be M12 x 1.5? Never played with that port but I think that is correct. Confirm?

Comfirm. They are M12. Im pretty sure the return is also the same thread

Anyway I fed mine from the coolant drain which is 1/4BSPT. I wouldn't mind someone confirming this as I can't find my receipts?

This will need to be a 90 bend to the braided line to another 90 bend into turbo m14 x 1.5.

You could/should/maybe feed from your proper water feed port though. if you decided to do this then measure the port difference, something like 50mm-100mm? And then take that off your 300mm length. Again my 300mm was centre to centre so tell Pirtek to take off 90 bend lengths.

Or as I have also suggested to MR. Buy the hose ends you can fit yourself (reusables) and buy 2m of hose- job done

Water drain.

I am unsure here as you have the OEM water drain on your thermostat housing so you will need to run that line and work that out yourself. I think your fitting on your thermostat housing is M12 x 1.5 as well but you'll need to confirm that or someone?

Page 41 on my link above explains the ports to tap into, not what you may have thought hey?

Recirculation Valve. Page 62

You will need to get some hose and run this to where your boost gauge goes with a T piece. I assume your boost line is right near your inlet manifold?

Just run a short hose from compressor housing fitting to the recirc valve. Boost gauge, wastegate reference and compensator should all come from manifold or T into the existing port on the intake of the cooler.

You will also need to do a T piece and run it into your pump as well. Assuming yours is compensated?

It is.

Clamps to suit but I only put a clamp on my recirc, very low pressure in these lines but should put clamps on I guess.

Page 64. Boost Controlled Solenoid Valve. Remove it, not needed.

Page 70. Get your actuator on and positioned to suit your mounting before our install mate to save time!

Boost controller, assuming you have one and the lines, etc?

Airbox to turbo, work that out, turbo to IC, work that out.

Matty, a couple of confirmation questions above, have I missed anything or made an error mate?

Darren, On the Friday, get your HT18 off, actuator on and positioned correctly for the install Saturday. Don't over torque the vband clamp on the turbo when orientating it to suit the actuator position if need be. If worried just measure the thread of their torque or the setting might be in that manual somewhere.

Reply With Quote

Reply With Quote

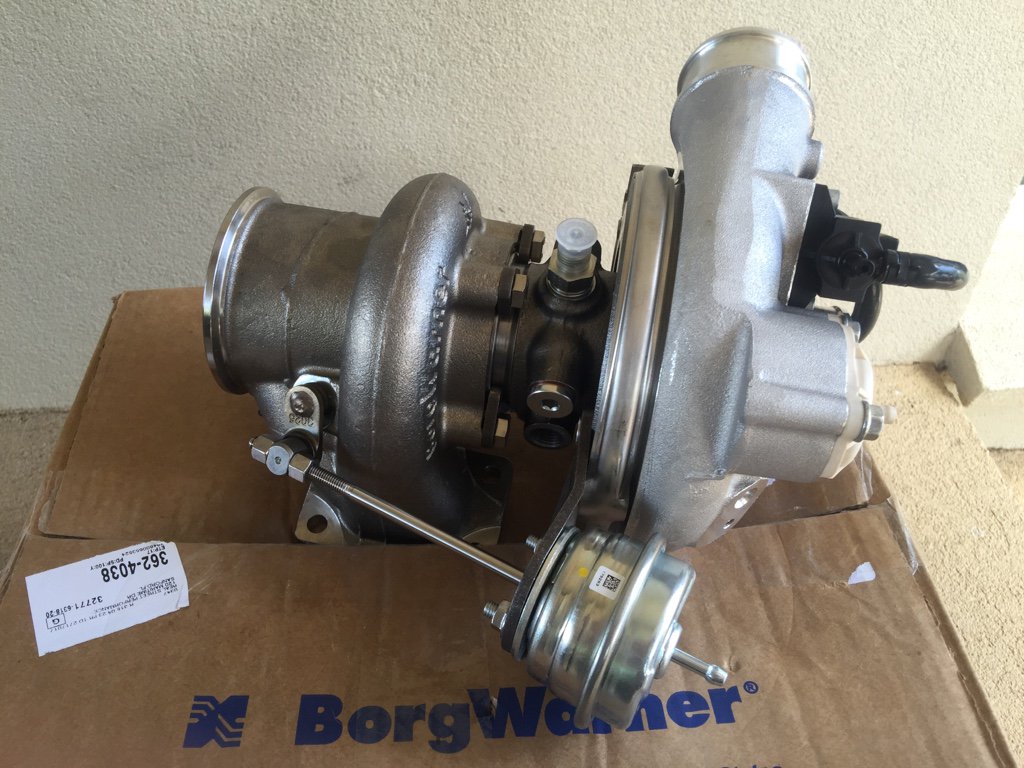

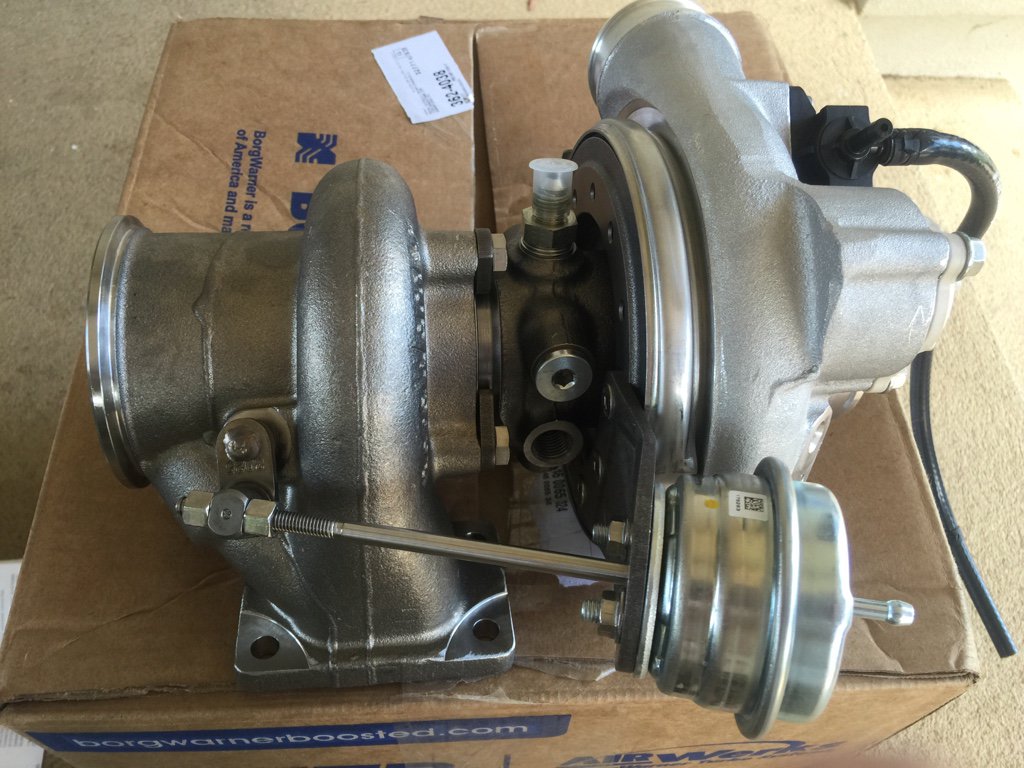

....... I'm a lucky bugger! I've got 2 of em!

....... I'm a lucky bugger! I've got 2 of em!