-

3rd October 2012, 08:33 AM

#1

Expert

-

-

3rd October 2012 08:33 AM

# ADS

Circuit advertisement

-

3rd October 2012, 02:38 PM

#2

-

-

3rd October 2012, 02:47 PM

#3

Patrol God

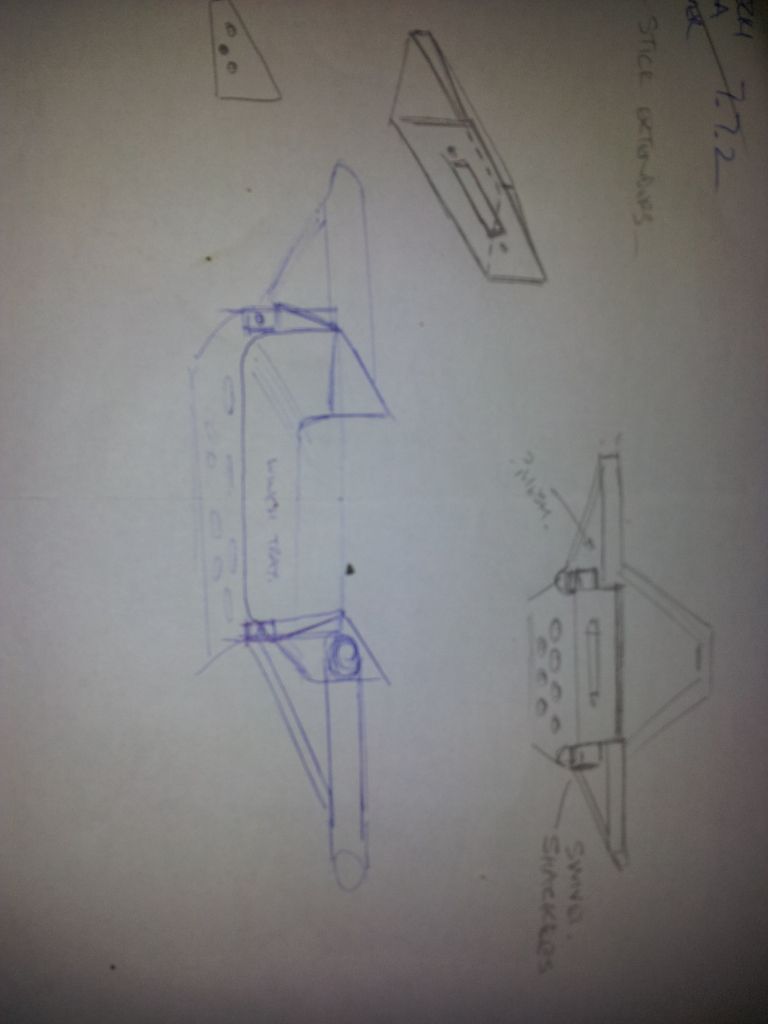

Try to think triangle all the time, this style bar is popular here on Comp 4x4's.

May I suggest you make the winch section seperate from the side wings.

If you go as hard as you say hitting trees etc, the outer wings bend very easy.

make it so they bolt on, your 4by will never looked trashed, maybe laser cut

some plate and make a jig for the wings, so they're all the same. Use thick

walled steam pipe if availabe.

Wouldn't waste my money on seamless pipe.

Last edited by threedogs; 3rd October 2012 at 02:51 PM.

04 ST 3lt auto, not enough Mods to keep me happy, but getting there

-

-

3rd October 2012, 06:32 PM

#4

Expert

Top idea, thanks for the advice.I'll weld up a plate on the end of the tube part me thinks

Y60 Patrol 4.2 d SWB in puke green

2" body lift, 2" pedders suspension lift, 35" Simex muds on excel 16" alloys, needs a turbo :/

-

-

3rd October 2012, 06:54 PM

#5

Patrol God

Yeah its hard to make the wings really sturdy, thats the tri angle theme. while you have it off make a plate to slide up the inside of chassis with nuts welded on to pick up the three holes on passenger side so you can fit a recovery plate see my vendor thread. or some M40 eye bolts as front recovery point, eye bolts would be more versitile, bigger the better but pricey. keep us updated. theres a small slide plate for the trailing arms as well, but talk about that later eh

04 ST 3lt auto, not enough Mods to keep me happy, but getting there

-

-

7th October 2012, 09:04 AM

#6

Expert

-

-

7th October 2012, 09:23 AM

#7

Patrol God

Where it bolts to the chassis rail are you beefing up your winch box, also need decent plate up inside chassis?.

Down under we make them from 10mm, 12mm plate. are you fitting a low or high mount.

Looks great by the way, just not what I see here thats all, It all depends how strong this "BOX" is bolted

between the chassis. what style of welder is it ,ARC, MIG,??? coming along nicely Bud, keep the pics coming

only zinc coated, grade 8 bolts too

Drain holes ????? or slots make it lighter as well

Looks like a bit of rust on the chassis that requires attention too, or just mud?

Last edited by threedogs; 7th October 2012 at 09:27 AM.

04 ST 3lt auto, not enough Mods to keep me happy, but getting there

-

-

7th October 2012, 09:53 AM

#8

Expert

Yeh cheers for that. Low mount winch, only a 12,000 lb jobbie, not winch challenge stylee lol I'm making an other piece of steel box to fit inside the chassis rails with welded on nuts. So there'll be 6 big ass bolts holding the tray bit on, same as the old pig tail ones. The box bit in the chassis will have the recovery swivels mounted in them and then bolted on the outside of the chassis too. The under side of the tray will be cut some more for drainage.

Chassis rails are a bit surface rusty and on the ever increasing list of to doooos :/

Mig welder.

My last winch bumper was 6mm and seemed to do ok but will look at some more strengthning on your advice, ta.

I'm using stainless bolts.

Y60 Patrol 4.2 d SWB in puke green

2" body lift, 2" pedders suspension lift, 35" Simex muds on excel 16" alloys, needs a turbo :/

-

-

7th October 2012, 10:33 AM

#9

Patrol God

Alls Good , for the drain holes. mark out a pattern with dividers centre punch drill then countersink a touch.

Looks more than strong enough all gunna be how this "box" is mounted, she''ll be right

04 ST 3lt auto, not enough Mods to keep me happy, but getting there

-

The Following User Says Thank You to threedogs For This Useful Post:

makeitfit (8th October 2012)

-

8th October 2012, 09:45 AM

#10

Expert

Originally Posted by

threedogs

Alls Good , for the drain holes. mark out a pattern with dividers centre punch drill then countersink a touch.

Looks more than strong enough all gunna be how this "box" is mounted, she''ll be right

You're obviously the man in the know on this stuff

I want to fit these swivel recovery points into the chassis ends, what are your suggestions ? Polite please lol

http://www.ebay.co.uk/itm/Recovery-s...item4a9ff5e3cf

Cheers Pete

Y60 Patrol 4.2 d SWB in puke green

2" body lift, 2" pedders suspension lift, 35" Simex muds on excel 16" alloys, needs a turbo :/

-

The tube part will also be 60mm and 3mm wall .

Reply With Quote

Reply With Quote

Time is never wasted when your wasted all the time

Time is never wasted when your wasted all the time

arse..............

arse..............